Food Value Chain – Distribution フードバリューチェーン

WORK’IN JAPAN

14.01.2021

This third article in our series about Food Value Chain is about Distribution.

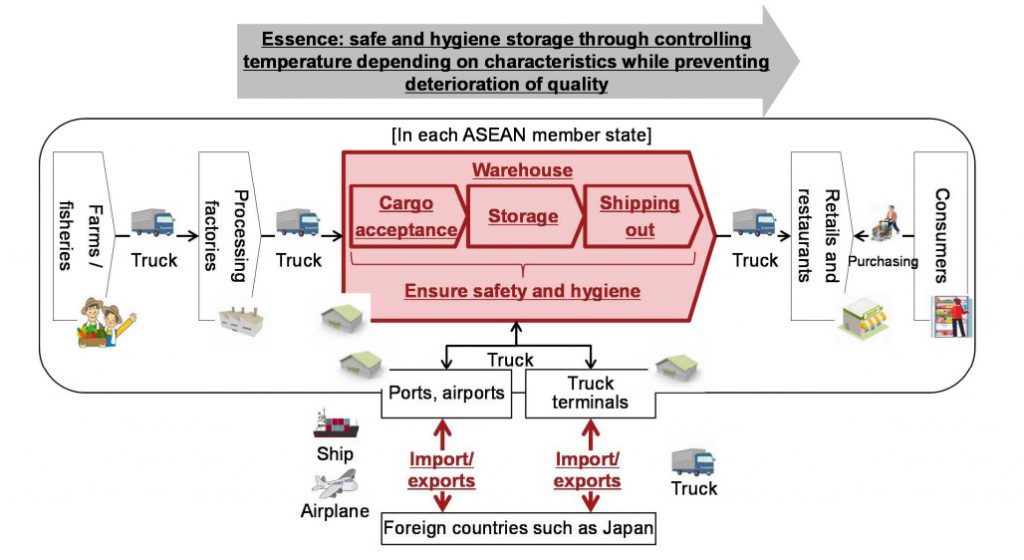

One of the biggest logistical obstacles in the operations involved in Food Value Chain is distribution. How do you create cold storage chains that span continents? Cross oceans? Many of these chains already exist, so infrastructure only needs to be improved, not reinvented.

By Panoha – Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=3672353

Distribution starts with getting products out from storage. Cold chain transportation is a large infrastructure of trucking and delivery routes that move products to their retail homes around the country or the world.

Trucks like the one pictured above are equipped with technology that keeps the contents of the truck chilled to the appropriate temperature. Ideally, cold chain is an uninterrupted series of refrigerated storage, trucks, and freight containers that allows for adequate distribution. As we spoke about in an early post, many of the ASEAN countries involved in this Food Value Chain with Japan have warmer temperatures and would then logically require greater attention to this leg of the Food Value Chain.

For logistics companies, this is an interesting challenge. In order to prevent quality deterioration, companies and purveyors involved in cold chain storage must be well equipped to handle a large variety of unpredictable circumstances.

There are many opportunities to build expert knowledge in each aspect of the distribution level of the food value chain. Statistics and data analysis skills are highly valuable at this level of the food value chain. If you have familiarity with cooling systems, logistics management, or the latest technology being used to transport goods around the world, this might be a field of interest for you. We are seeing now, with the COVID-19 vaccine distribution, just how valuable cold storage chain infrastructure can be.